SKU

GSB051H

Brand:

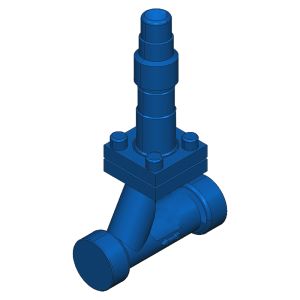

Hansen GSB051H, 1/2 Shut-off Valve, Globe, Bolted Bonnet, Socket Weld, Handwheel, T-Style

Hansen GSB051H, 1/2 Shut-off Valve, Globe, Bolted Bonnet, Socket Weld, Handwheel, T-Style

List Price

$263.00

List Price

$263.00

Web Price

$185.85

Details

The advanced design and materials of the Hansen Steel Body Socket Weld Refrigerant Valves make them stronger and far superior to other commonly available products. This is especially true in regard to leakage from seats, stems, bonnets, and piping connections. Socket weld steel bodies permit these valves to be quickly and easily welded directly into piping without the inconvenience of pipe threading or using bulkier iron-flanged valves with socket weld steel flanges requiring bolts, nuts, and gaskets. Compared to butt weld valves, the Hansen socket weld bodies allow quicker welding, easier pipe alignment, and cleaner pipe and valve interiors.Applications:Typical uses include:Ammonia refrigeration system suction, liquid, discharge, recirculating liquid, hot gas, thermosyphon, and oil lines, using handwheel or seal cap models.Steel pipe portions of halocarbon, commercial, industrial, and air conditioning systems, using seal cap models.Valves are also avilable for other fluids such as propane, propylene, and glycol with compatible seals. Contact factory with specific fluid and application details for written approval.The low friction, non-leak stem seal design permit the use of chain actuation for crossover applications without the need to retighten the packing.Additional Features:Globe and angle valves availableLow pressure drop designTeflon sear dsic.Chain actuators available 1-1/2"/2-1/2"(40mm-65mm)Suitable for R717 (ammonia), R22, R134a, R507, R404a, R744 (Co2) and other Hansen approved refrigerantsValves for 600 psig (41 bar g) SWP available.Extended neck availble for additional insulation clearance.

More Information

| Weight | 6.000000 |

|---|---|

| Condition | New |

| Brand | Hansen |

| Port Size | 1/2" |

| Ball Bearings | Stainless steel |

| Body | Forged steel, ASTM A105 |

| Bonnet | Ductile iron, ASTM A536 |

| Bonnet Style | Bolted Bonnet |

| Handwheel | Zinc plated alloy |

| Disc Holder | Plated steel |

| Seal Cap | Glass-filled polymer, Neoprene O-ring seal, safety vented |

| Seat Disc | Retained PTFE Teflon |

| Stem | Polished stainless steel |

| Stem Packing | Graphite composite plus neoprene O-ring in series |

| Valve Body Type | Globe |

| Packing Nut | Zinc plated steel |

| Safe Working Pressure | 400 psig (28 bar g) standard, 600 psig (41 bar g) upon request |

| Operating Temperature | Standard, -60°F to 240°F (-51°C to 115°C), temperatures below -60°F (-51°C) to -76°F (-60°C) at coincident pressures (Bolted bonnet only) Optional, -20°F to 300°F (-29°C to 149°C) |

| Connection Style | Socket Weld |

| Width | 9 |

| Height | 5 |

| Length | 10 |

| Depth | 9.5 |

Resources

Reviews

Product Questions